Main Article Content

Abstract

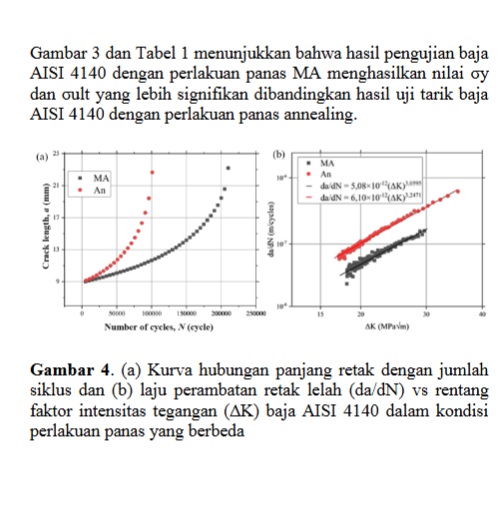

Penelitian ini mengkaji perilaku perambatan retak lelah pada baja AISI 4140 yang diberi perlakuan panas multi-austempering. Spesimen uji tarik dan perambatan retak lelah (Fatigue Crack Proopagation-FCP) disiapkan masing-masing sesuai dengan ASTM E8 dan ASTM E647. Multi-austempering dilakukan dengan memanaskan spesimen pada suhu austenit selama 10 menit menggunakan koil pemanas induksi. Spesimen kemudian direndam dalam salt bath untuk setiap waktu transformasi isotermal 60 menit pada tiga tingkat suhu austempering dari 312°C hingga 412°C dengan kenaikan suhu 50°C. Uji pertumbuhan retak tarik dan lelah dilakukan pada spesimen anil dan multi-austemper. Telah diamati bahwa perlakuan panas multi-austempering secara signifikan meningkatkan sifat tarik dan sifat FCP baja AISI 4140. Pengamatan mikrostruktur menunjukkan bahwa fasa bainitik dan sisa austenit meningkatkan kekuatan tarik dan menurunkan laju perambatan retak lelah (da/dN). Ditemukan bahwa struktur bainitik merupakan penghalang yang efektif dalam mengurangi perambatan retak lelah seiring dengan meningkatnya siklus pembebanan lelah.

Keywords

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

References

- ASTM E647, Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM International, West Conshohocken, PA, 2000.

- ASTM-E8M, Standard Test Methods for Tension Testing of Metallic Materials, West Conshohocken, PA, United States, DOI (2004).

- D. Birenis, Y. Ogawa, H. Matsunaga, O. Takakuwa, J. Yamabe, Ø. Prytz, A. Thøgersen, Hydrogen-assisted fatigue crack propagation in a pure BCC iron. Part II: Accelerated regime manifested by quasi-cleavage fracture at relatively high stress intensity range values, MATEC Web Conf., 165 (2018) 03010.

- H.F. Lan, L.X. Du, Q. Li, C.L. Qiu, J.P. Li, R.D.K. Misra, Improvement of strength-toughness combination in austempered low carbon bainitic steel: The key role of refining prior austenite grain size, Journal of Alloys and Compounds, 710 (2017) 702-710.

- J.G. Speer, D.V. Edmonds, F.C. Rizzo, D.K. Matlock, Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation, Current Opinion in Solid State and Materials Science, 8 (2004) 219-237.

- L. Oger, S. Vernier, P. Joly, J.M. Cloue, L. Laffont, E. Andrieu, Study of the relationships between microstructure and local mechanical properties in the ductile-to-brittle transition of a bainitic steel containing local segregations, Materials Today Communications, 37 (2023) 107436.

- M. Badaruddin, R.A. Ainnayah, R.N. Wijaya, S. Sumardi, Investigation of Austempering Effect on Fatigue Crack Growth of AISI 4140 Steel, Defect and Diffusion Forum, 431 (2024) 115-120.

- M. Badaruddin, Sugiyanto, H. Wardono, Andoko, C.J. Wang, A.K. Rivai, Improvement of low- cycle fatigue resistance in AISI 4140 steel by annealing treatment, International Journal of Fatigue, 125 (2019) 406-417.

- M. Badaruddin, Sugiyanto, S. Sumardi, D. Asmi, Improvement of the fatigue crack growth resistance in AISI 4140 steel under single- and multi-austempering heat treatments, Results in Engineering, 21 (2024) 101814.

- M.M. Bilal, K. Yaqoob, M.H. Zahid, E.u. haq, W.H. Tanveer, A. Wadood, B. Ahmed, Effect of austempering conditions on the microstructure and mechanical properties of AISI 4340 and AISI 4140 steels, Journal of Materials Research and Technology, 8 (2019) 5194-5200.

- X.L. Wang, K.M. Wu, F. Hu, L. Yu, X.L. Wan, Multi-step isothermal bainitic transformation in medium-carbon steel, Scripta Materialia, 74 (2014) 56-59.

References

ASTM E647, Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM International, West Conshohocken, PA, 2000.

ASTM-E8M, Standard Test Methods for Tension Testing of Metallic Materials, West Conshohocken, PA, United States, DOI (2004).

D. Birenis, Y. Ogawa, H. Matsunaga, O. Takakuwa, J. Yamabe, Ø. Prytz, A. Thøgersen, Hydrogen-assisted fatigue crack propagation in a pure BCC iron. Part II: Accelerated regime manifested by quasi-cleavage fracture at relatively high stress intensity range values, MATEC Web Conf., 165 (2018) 03010.

H.F. Lan, L.X. Du, Q. Li, C.L. Qiu, J.P. Li, R.D.K. Misra, Improvement of strength-toughness combination in austempered low carbon bainitic steel: The key role of refining prior austenite grain size, Journal of Alloys and Compounds, 710 (2017) 702-710.

J.G. Speer, D.V. Edmonds, F.C. Rizzo, D.K. Matlock, Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation, Current Opinion in Solid State and Materials Science, 8 (2004) 219-237.

L. Oger, S. Vernier, P. Joly, J.M. Cloue, L. Laffont, E. Andrieu, Study of the relationships between microstructure and local mechanical properties in the ductile-to-brittle transition of a bainitic steel containing local segregations, Materials Today Communications, 37 (2023) 107436.

M. Badaruddin, R.A. Ainnayah, R.N. Wijaya, S. Sumardi, Investigation of Austempering Effect on Fatigue Crack Growth of AISI 4140 Steel, Defect and Diffusion Forum, 431 (2024) 115-120.

M. Badaruddin, Sugiyanto, H. Wardono, Andoko, C.J. Wang, A.K. Rivai, Improvement of low- cycle fatigue resistance in AISI 4140 steel by annealing treatment, International Journal of Fatigue, 125 (2019) 406-417.

M. Badaruddin, Sugiyanto, S. Sumardi, D. Asmi, Improvement of the fatigue crack growth resistance in AISI 4140 steel under single- and multi-austempering heat treatments, Results in Engineering, 21 (2024) 101814.

M.M. Bilal, K. Yaqoob, M.H. Zahid, E.u. haq, W.H. Tanveer, A. Wadood, B. Ahmed, Effect of austempering conditions on the microstructure and mechanical properties of AISI 4340 and AISI 4140 steels, Journal of Materials Research and Technology, 8 (2019) 5194-5200.

X.L. Wang, K.M. Wu, F. Hu, L. Yu, X.L. Wan, Multi-step isothermal bainitic transformation in medium-carbon steel, Scripta Materialia, 74 (2014) 56-59.